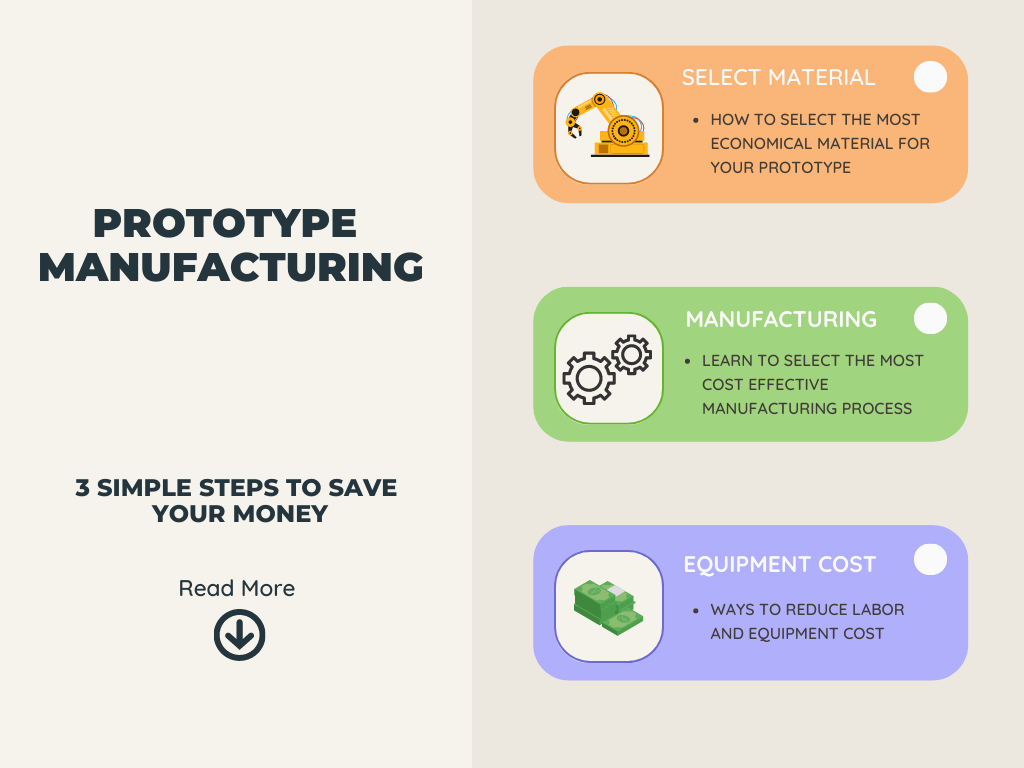

Prototype Manufacturing is the process of creating a physical part or component before mass manufacturing. Its crucial step of product development because it allows you to test and refine the concept design, identify potential issues, and make essential improvements or enhancements in the design. You can use following steps to make your prototype manufacturing budget friendly

1.Material Selection for Prototype

Selecting the right materials for your prototype can have a significant impact on the success of your product testing and manufacturing. Product Functionality and environment of its operation directly govern the material selection process.

For example, if your product is designed for marine industry, it should be made of corrosion resistant materials like stainless steel. Similarly, if your product’s function is to assist human in weight handling then selected material must have good strength to weight ratio.

Some easy-to-use softwares can help you efficiently do a brief material study and can recommend you suitable material for your prototype manufacturing.

I have personally tested these 2 softwares and they are beginner friendly.

- CES Selector: CES Selector is a software tool that help you identify and compare materials based on their properties. It includes a database of over 7,000 materials and allows users to compare materials side-by-side and generate costing reports.

- MatWeb: MatWeb is a free online database of materials properties and performance data for over 118,000 materials. It allows users to search for materials by keyword or property, and provides detailed data on mechanical, thermal, and physical properties.

Overall, material selection software tools can be helpful in identifying and evaluating materials for prototype manufacturing. When selecting a software tool, consider factors such as cost, features, and compatibility with your existing software and hardware.

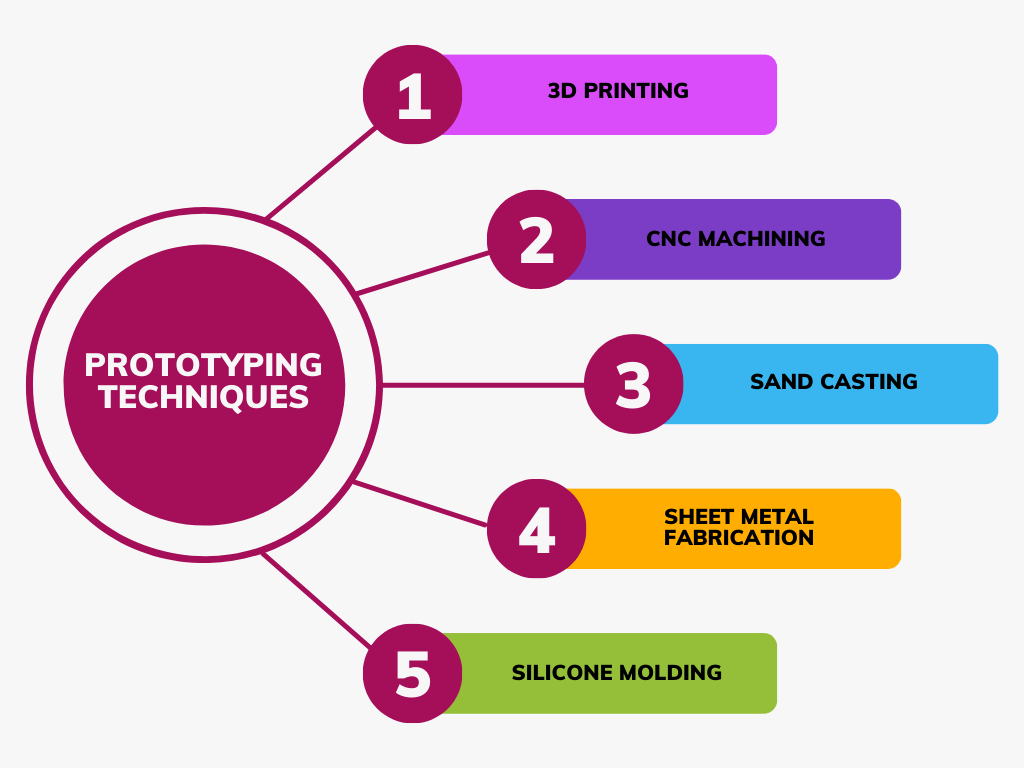

2. Prototyping Technique

Selecting the right manufacturing technique for your prototype will depend on several factors, including the complexity of the design, the desired level of accuracy, and the materials finalized. Some cost-effective prototyping techniques are mentioned below.

2.1 3D Printing for Prototype Manufacturing

3D printing, also known as additive manufacturing, has become a popular technique for prototype manufacturing. You should prefer 3d printing due to following reasons.

- Make it Quick: 3D printing allows for rapid prototyping and can produce a physical model of your design quickly.

- Design Flexibility: 3D printing enables you to create complex geometries and intricate designs that may be difficult or impossible to produce with traditional manufacturing techniques.

- Low Volume Production: 3D printing is ideal for low-volume production runs since it doesn’t require the creation of expensive molds or tooling, which can be cost-prohibitive for small runs.

- Design Validation: 3D printing makes design iteration easy. 3D printing can be used to create functional prototypes that closely resemble the final product. This allows you to validate your design before committing to more expensive manufacturing processes.

2.2 Making Rapid Prototyping Cost Effective

By using the following strategies, you can ensure that 3d printing is cost effective for you.

Design Optimization: Design optimization is the first step to reduce material usage and minimize build volume. Design optimizations are mostly done in your CAD or 3d printing software. Sometimes prototypes don’t need to be very detailed and fully functional. You can make your prototyping budget friendly by focusing more on functional aspects and temporarily ignoring the aesthetic details in design.

Pricing criteria for 3D printing is mostly based on weight and volume of product. You can modify the geometry of your model, so it needs minimum building support. You can also do topology optimizations in your design to minimize the weight of your product.

Topology optimization is a mathematical method used in engineering design to optimize the material layout within a given design space, in order to achieve the best performance based on specified criteria while minimizing the material used. You can READ MORE about this concept.

2.3 Material Selection for 3d printing prototypes

- Using recycled materials as 3D printing filaments can save cost of prototyping. recycled materials are often cheaper than virgin materials. They can also cut down your waste disposal costs, energy costs, and transportation costs. It is important to note that recycled materials may have variations in quality and consistency, which can impact the quality of the final product.

- Materialise Magics: Materialise Magics is a software tool for 3D printing that includes material selection capabilities. It allows users to evaluate and compare materials for their 3D printing projects, and provides data on mechanical, thermal, and physical properties.

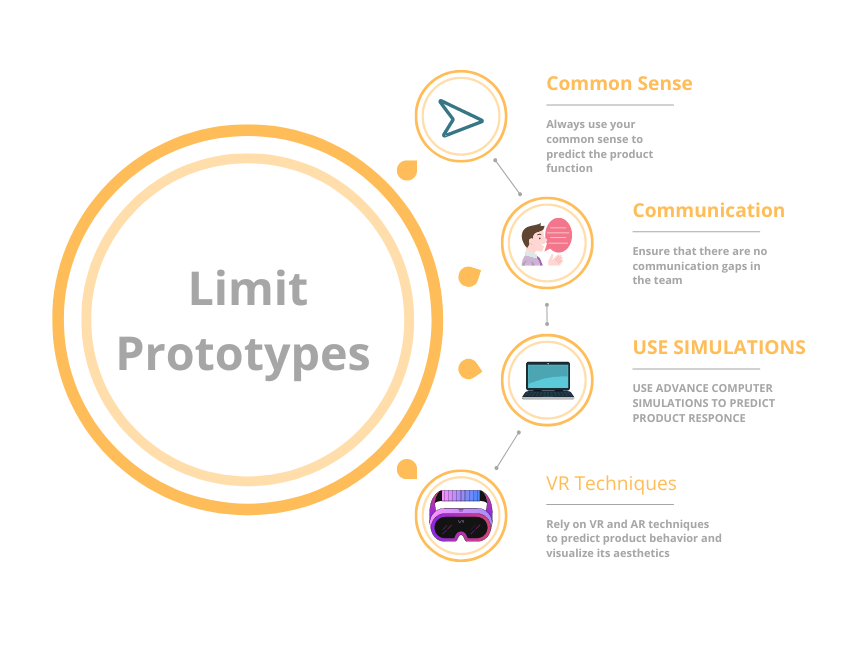

3. Limiting Iterations in Prototyping

Aim of the prototype is to develop working product to and check out its functionality in real world, to achieve this goal you don’t need to practically manufacture the prototype, with modern softwares you can test out the product behavior without spending any money. This technique is known as Finite Element Analysis and helps you to test the product in virtual environment. It doesn’t eliminate the need of an actual product prototype. Instead, it should only be used to minimize the number of iterations needed to come up with ultimate results.

Testing product functionality and behavior with help of mathematical models is known as Computer Simulation, this technique helps user to define testing criteria in the virtual environment and analyze potential real-world behavior of the product. User can set up following computer simulations to predict product outcomes.

- Drop test: This technique is very useful to test out delicate products. you can define the target height and can test virtually if your product will survive the fall, this simulation study can accurately predict the height threshold of your product.

- Stress Analysis: This simulation helps you determine the strength of your product. It also generates the value for Factor of safety. FOS value predicts the maximum load bearing capacity of a product without breaking.

- Deformation Analysis: This analysis helps you determine the maximum elastic deformation your product can take under stress without losing its shape permanently, you can get exact measurements of deformity induced in your product.

Computer simulations don’t eliminate the need of prototype manufacturing. They reduce the number of iterations required, always test your CAD design in virtual environment before doing any type of prototype.

This brief guide can also help you to learn about DESIGNING A PRODUCT more efficiently.

4. Labor and Equipment Cost

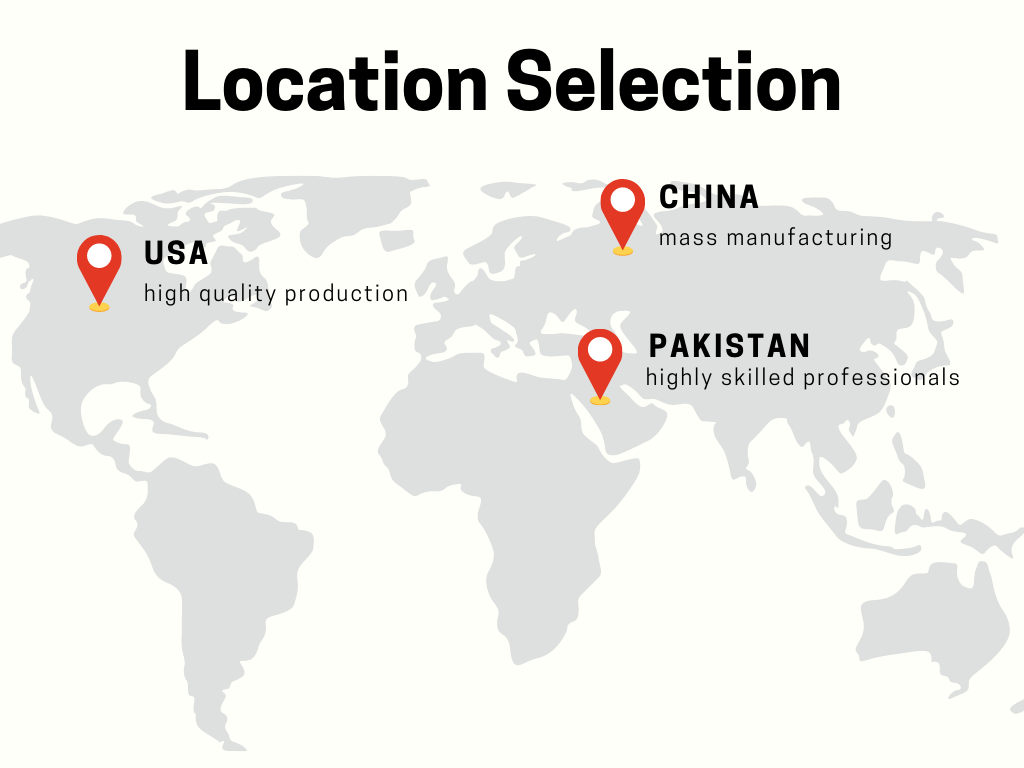

If you have no technical background, you may need professional help for practical manufacturing. Your target selling market and your prototype manufacturing location can be different, its always a good idea to get multiple quotations from professionals based in different geographical locations.

if you need to source some special tools you can explore garage sales. Borrowing tools from someone close to you is also another option.

For professional assistance you should collaborate someone through Fiverr. Fiverr is very cost-effective platform to hire professional designers and prototype manufacturers.

1. Final Words

Prototype manufacturing is an important step in product development. It allows you to test and refine the concept design, identify potential issues, and make essential improvements or enhancements. Although prototype manufacturing can be costly, there are several steps you can take to validate your design without exceeding your budget. These include selecting the right materials for your prototype using software tools such as CES Selector and MatWeb.

Cost-effective prototyping techniques such as 3D printing can reducing number of iterations needed by testing the product behavior with the help of computer simulations

If you need any professional help or a free advice, please CONTACT HERE.